Grey EPS – Graphite-Infused Expanded Polystyrene for High-Performance Thermal Insulation

High-Performance Grey EPS Insulation

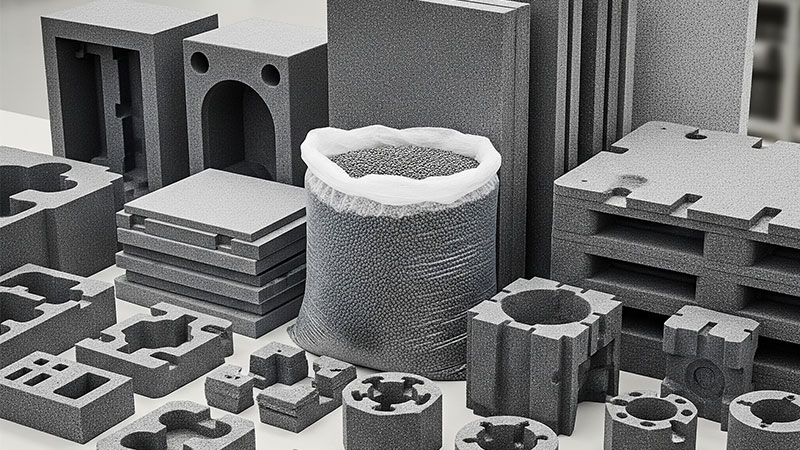

Our Grey EPS is a premium insulation material manufactured by infusing standard expanded polystyrene beads with high-purity graphite particles. The graphite additive improves thermal performance by reflecting radiant heat, providing up to 20% better insulation compared to traditional white EPS of similar thickness. This advanced material is lightweight, durable, moisture resistant, and fully recyclable—making it ideal for sustainable, energy-efficient building solutions.

Grey EPS Suspension Technical Specifications

Typical Properties*

| Grade | Bead Size, mm | Density, g/l |

| Test Method | ASTM D 1921 | Internal test method |

| G-301 | 1.00-1.60 | 14-18 |

| G-302 | 0.85-1.25 | 16-20 |

| G-303 | 0.70-0.90 | 18-25 |

| G-401 | 0.50-0.80 | 22-30 |

| G-501 | 0.40-0.60 | 25-35 |

Grey EPS Suspension Process

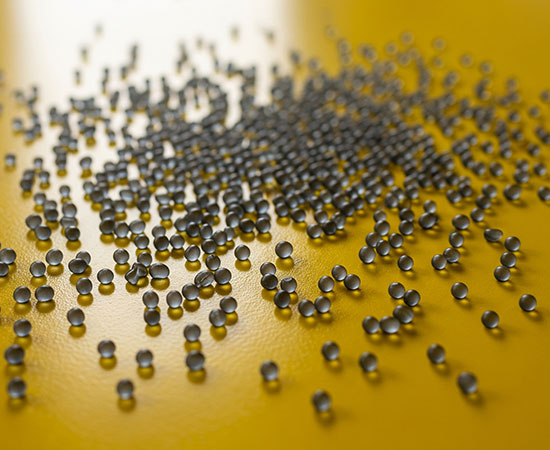

The base material for Grey EPS starts with the suspension polymerization process, where styrene monomers are dispersed in water and polymerized into polystyrene beads under controlled conditions using a suspension agent. This process produces the raw beads that will later be expanded into EPS foam.

While the suspension polymerization itself does not produce the grey color, the introduction of graphite or carbon black additives either during or after the suspension process creates the characteristic grey beads. These additives optimize bead size, distribution, and cell structure, resulting in superior thermal insulation properties for the finished Grey EPS product.

Grey EPS Extrusion

Grey EPS (Expandable Polystyrene) Extrusion is an advanced manufacturing process that produces high-performance expanded polystyrene with enhanced thermal insulation, mechanical strength, and durability. The distinctive grey colour comes from the addition of graphite particles during production, which reflect and absorb radiant heat, improving energy efficiency.

How It Works

In the extrusion process, polystyrene beads are expanded using steam and blowing agents, then extruded into uniform shapes or profiles. The addition of graphite or other infrared absorbers reduces thermal conductivity, making Grey EPS up to 20% more efficient than standard white EPS.

Technical details of Grey EPS Extrusion

| Item | Standard | Technical requirements | Typical value |

| Shape | / | Ellipsoid or spherical | ball |

| Color | / | Black | Black |

| Blowing agent content % | QB/T4009-20 10 | 5.0~7.0 | 5. 2-5.7 |

| 95% particle size range (mm). | QB/T4009-20 10 | 1.0-2.0 | 1.0-1.6 |

| Thermal conductivity (W/(mk)). | GB/T 10295-2008 | ≤0.032 | 0.030 |

| Oxygen index(%). | GB/T 2406.2-2009 | ≥30% | 31 |

| Compressive strength (KPa) @ 20kg/m3 | GB/T 8813-2008 | ≥100 | 120 |

| Dimensional stability, % | GB/T 8811-2008 | ≤3 | 0.17 |

| Water vapor transmission coefficient, ng/(Pa.m.s) | GB/T 2411-1998 | ≤4.5 | 3.5 |

| Water absorption (by volume fraction), % | GB/T 8810-2005 | ≤4 | 2.9 |

| Bending load at break, N | GB/T 8812.1-2007 | ≥25 | 37 |

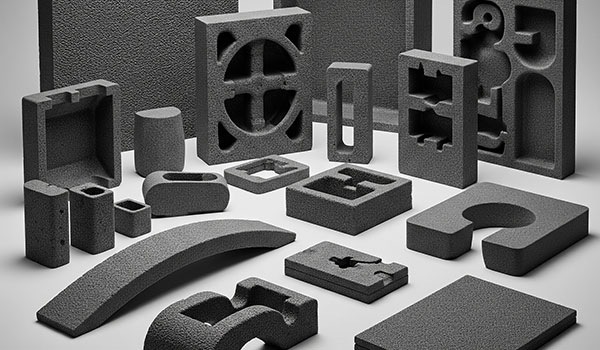

Key Features and Benefits of Grey EPS

- Superior Thermal Insulation- Graphite particles reflect radiant heat, reducing heat transfer and enhancing energy efficiency.

- Lightweight & Durable – Easy to handle and install while maintaining excellent compressive strength.

- Moisture Resistant– Closed-cell structure prevents moisture absorption, protecting against mold and decay.

- Eco-Friendly – Made from recyclable materials contributing to sustainable building practices.

- Cost-Effective – Provides better insulation performance at comparable or reduced thickness, lowering overall costs.

Grey EPS is widely used in:

- Building Insulation- Roofs, walls, floors, and foundations in residential, commercial, and industrial buildings.

- Cold Storage & Refrigeration- Effective thermal barriers for temperature-controlled environments.

- Prefabricated & Modular Construction – Lightweight panels that enhance insulation without excess weight.

- Underfloor Heating Systems – Efficient insulation to maintain consistent warm floors.